Chemicals, paints, resins, and other vital liquids are essential to various industries and manufacturing processes. Transporting these goods requires strict precautions to ensure safe handling and delivery.

Our bulk liquid trailers are specifically designed to meet all necessary requirements for transporting liquid bulk, including chemicals. Trained drivers, equipped with the expertise to handle these specialized trailers, ensure secure and efficient delivery from the source directly to production facilities, maintaining safety and reliability at every step.

Technical Specifications

Capacity

37,5 cbm

Thermal Insulation

Operating Temperature

120 Degree C

Test Pressure

4,0 Bar

Operating Pressure

2,6 Bar

Total Weight

39,0 to

Features

Body Type

Made of AISI 316Ti (DIN 1.4571) quality stainless steel material, having a filling manhole or cleaning manhole conforming to EN 140 25 standard on each compartment separated by breakwaters fitted in accordance with EN 14025 standard for ease of cleaning, with sloping design to prevent fluid retention in the tank ,conforms to EN 14025 standard, with cylindrical section body with L4BH ADR code

Chassis Type

Made of high strength AISI 304 (DIN 1.4301) quality stainless steel material, by two special I cross sectioned welded profiles with increased strength and special design stainless steel cross connection. Electropolishing applied in the standards defined in accordance with ISO 15730: 2000 provides reliable corrosion protection, visual aesthetics and surface gloss. Surface shine protects the same look for many years. Hydrogen fragility is eliminated.

Brake System

There is a dual-circuit electro-pneumatic braking system with EBS 2S/2M antiblocking system suitable for UN ECE R13 regulation and an integrated RSS electronic stability control system in the braking system.

Tyre Size

Tyre size 385/65 R 22.5

Axles

BPW air suspension and disc brake axle with 3 x 9 tons capacity

Electric System

ASPÖCK lightning installation with 24 V LED side position lamp and 1×15- pin sockets, in compliance with Regulation UN ECE R48 and ADR Legislation

Compartment Volume Distributio

1 compartment, 37,500 l capacity tanker

Number Of Compartments

1 Compartment and inside there will be a baffle for per 7500 l volume.

Discharge Valve

Equipped with manually controlled butterfly outlet valve with nominal diameter DN80 in compliance with Standard EN14432

Hose Carrier

There is a pvc hose carrier which can store 6.000 mm hose in 1 x DN 150 size

Certification

Full compliance with ADR regulations (ADR 4.3.4, ADR 6.8, EN14025, EN14433, EN14432 and EN3-7:2004)

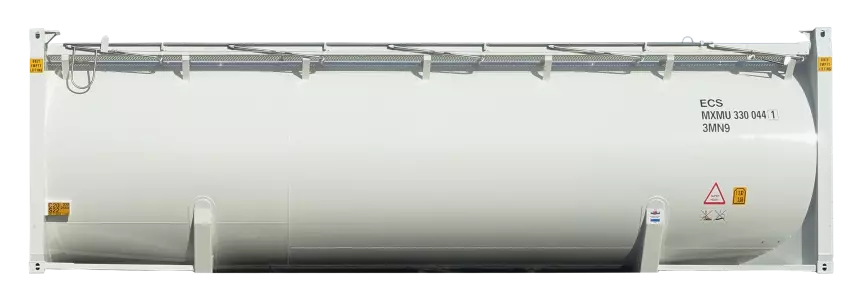

Pressurised Containers - 20ft / 30ft / 40ft

A standard 20 ft aluminium pressurised container has a volume of approximately 26.5 m³, weighs ± 1,750 kg and has 3 manholes. The slightly narrower ISO version (width 2,438 mm) has a volume of approximately 25 m³.

A standard 30 ft aluminium pressurised container has a volume of approximately 42 m³, weighs ± 2,000 kg and has 4 manholes. The slightly narrower ISO version (width 2,438 mm) has a volume of approximately 38.5 m³.

A standard 40 ft aluminium pressurised container has a volume of approximately 58.5 m³, weighs ± 2,500 kg and has 6 manholes. The slightly narrower ISO version (width 2,438 mm) has a volume of approximately 52.5 m³.

Chasis for Container - 20ft ISO / SWAP

Our shortest and lightest version is the 20 ft ISO tank container chassis, with the 20 ft ISO tank container at the very back of the chassis.

The LAG 20 ft SWAP tank container chassis is the most versatile chassis in the portfolio. Depending on customer wishes, numerous configurations for spill tray and access options to the container are possible.

Chasis for Container - 30ft / 40ft

For the 30/40 ft tank container chassis, we have the robust classic version with a closed rear, where there is a continuous spill tray between the 30 ft and 40 ft arms, flanked by walkways. We also have the version with an open rear, where we guarantee maximum accessibility with the low entry platform and the interrupted 40 ft arm.

Liquids we carry

Class 3

Flammable liquid substances

Class 5.1

Oxidizing Liquids

Class 5.2

Organic Peroxides

(Highly Reactive Substances)

- Gasoline (Petrol) [UN 1203]

- Diesel fuel [UN 1202]

- Ethanol [UN 1170]

- Acetone [UN 1090]

- Toluene [UN 1294]

- Xylene [UN 1307]

- Methanol [UN 1230]

- Hydrogen Peroxide (over 60%) [UN 2015]

- Nitric Acid (above 70%) [UN 2031]

- Sodium Hypochlorite Solution [UN 1791]

- Ammonium Nitrate Solution [UN 2426]

- Methyl Ethyl Ketone Peroxide [UN 3105]

- Benzoyl Peroxide [UN 3104]

- Cumene Hydroperoxide [UN 3109]

Class 6.1

Toxic Liquids

Class 6.2

Infectious Substances

(Liquids Containing Pathogens)

Class 8

Corrosive Liquids

- Phenol [UN 1671]

- Chloroform [UN 1888]

- Bromine [UN 1744]

- Hydrofluoric Acid Solution [UN 1790]

- Acetonitrile [UN 1648]

- Blood samples containing pathogens [UN 3373]

- Clinical waste (liquid form) [UN 3291]

- Cultures of viruses and bacteria (liquid form) [UN 2814]

- Sulfuric Acid (Battery Acid) [UN 1830]

- Hydrochloric Acid [UN 1789]

- Sodium Hydroxide Solution [UN 1824]

- Formic Acid [UN 1779]

- Glacial Acetic Acid [UN 2789]

Let’s talk about your project

With a dedicated customer support team available 24/7, we’re ready to address your questions and concerns anytime. Choose BlackBull, and experience hassle-free transport that prioritizes your needs and safety every step of the way!